Over the past year, I’ve noticed a shift in how small and medium-sized businesses are talking about artificial intelligence.

The early conversations were predictable:

What tools should we use?

Are we falling behind?

Is AI going to replace jobs?

More recently, the questions have become quieter — and better:

Where would this actually help us?

What problem would we solve first?

How do we avoid getting this wrong?

That shift matters.

Because in my experience, most SMEs don’t have an AI problem.

They have something more fundamental.

The real issues SMEs are dealing with

When I spend time inside regional businesses — manufacturing, food, wine, logistics, services — the challenges are remarkably consistent:

- Processes that have grown organically but are no longer clear

- Bottlenecks that everyone feels but no one has time to step back and fix

- Manual reporting and compliance work consuming valuable people

- Decisions delayed because information is fragmented or late

- Good people stretched thin, holding too much knowledge in their heads

None of these are technology problems.

They are process, flow, and decision-making problems.

And this is where AI conversations often go wrong.

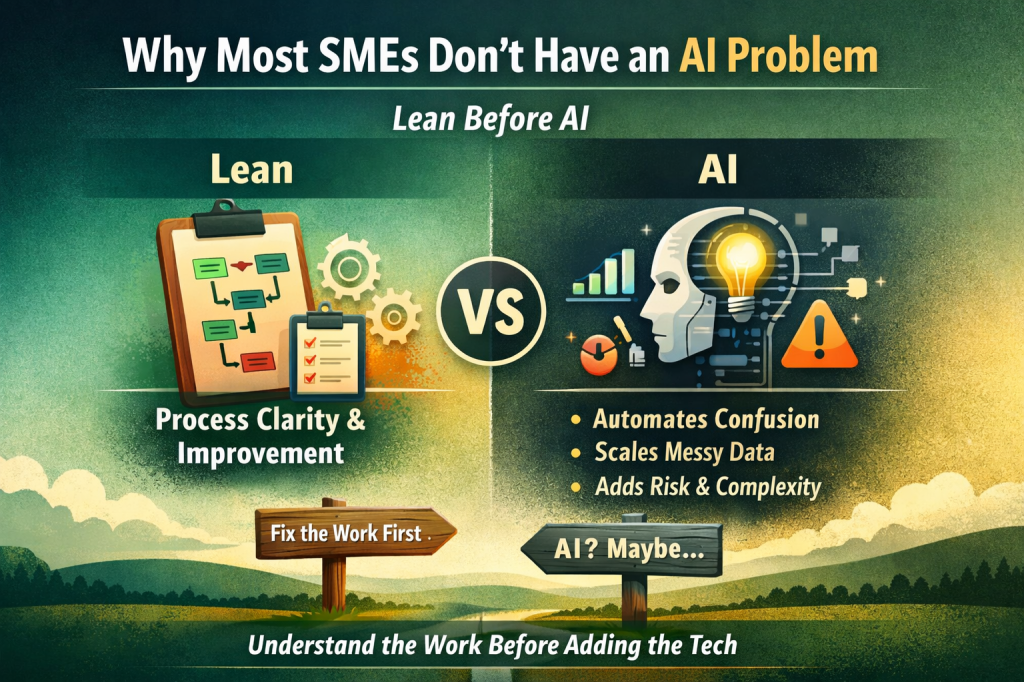

When AI shows up too early

AI is powerful — but it’s also very good at amplifying whatever already exists.

If a process is unclear, AI will automate confusion.

If data is messy, AI will scale inconsistency.

If decision rights are vague, AI will create new risks rather than remove them.

This is why many SMEs experiment with AI tools and walk away unconvinced.

Not because AI doesn’t work — but because it was applied before the work was understood.

Lean before AI

Lean thinking starts with different questions:

- How does work actually flow?

- Where is time, effort, or value being lost?

- Where are decisions slow, manual, or repeated?

- What creates frustration for customers or staff?

Often, answering these questions delivers immediate improvement without any technology at all.

And interestingly, once that clarity exists, something else happens:

The role of AI becomes obvious — and usually much smaller than first imagined.

Instead of “AI everywhere”, it becomes:

- AI assisting a specific decision

- AI reducing a narrow reporting burden

- AI supporting, not replacing, experienced people

That’s a far safer place to start.

A more sensible way to think about AI

For SMEs, AI works best when it is treated as:

- A productivity enabler, not a strategy

- A decision support tool, not a decision maker

- Something to be tested carefully, not rolled out broadly

This approach aligns closely with how Lean improvement has always worked:

- Small experiments

- Clear measures

- Human judgement retained

- Learning before scaling

In that sense, AI doesn’t replace Lean — it benefits from it.

Why this matters now

New Zealand’s AI strategy is deliberately focused on adoption, not invention.

That’s sensible.

But adoption without discernment creates as many problems as it solves.

Regional businesses, in particular, need approaches that:

- Respect limited time and capital

- Build confidence, not dependency

- Leave capability inside the organisation

Starting with Lean does exactly that.

A closing thought

The most encouraging sign I’m seeing isn’t that SMEs are rushing into AI.

It’s that more of them are slowing down and asking better questions.

That’s usually where real improvement begins.

Leave a comment