-

Continue reading →: 30 Years of Kaizen – A Journey from Lean to Enterprise Excellence

Continue reading →: 30 Years of Kaizen – A Journey from Lean to Enterprise ExcellenceThis year marks 30 years since I was first introduced to Kaizen — a simple idea that turned into a lifelong pursuit. Back in the mid-1990s, I had my first real exposure to what we then called the Toyota Production System. It was a formative experience, and I captured some…

-

Continue reading →: Productivity, AI and Prosperity – Why Leadership Is the Missing Link

From Productivity to Prosperity: The Role of Lean Thinking in an AI Age 1. The Productivity Paradox Is Back (and Bigger) Set the scene: Introduce the paradox: “We have more tools, more data, and more automation than ever before — yet productivity growth is flat, and work feels harder, not…

-

Continue reading →: Why Most SMEs Don’t Have an AI Problem

Over the past year, I’ve noticed a shift in how small and medium-sized businesses are talking about artificial intelligence. The early conversations were predictable:What tools should we use?Are we falling behind?Is AI going to replace jobs? More recently, the questions have become quieter — and better:Where would this actually help…

-

Continue reading →: Why Most Organisations Get Lean Wrong – And How the Shingo Model Fixes It

For more than 30 years, organisations around the world have invested heavily in Lean tools: 5S, Kanban, Value Stream Mapping, A3 problem solving, standard work and more. And those tools can deliver real short-term results. Output rises, waste falls, and improvement activity becomes visible. Yet in many organisations, something predictable…

-

Continue reading →: Toyota using AI to Reinvent Kaizen and Boost Productivity

AI for Toyota? For decades, Toyota has been the global benchmark for operational excellence through the Toyota Production System (TPS) and its core principle of Kaizen—continuous improvement. But even the gold standard of Lean manufacturing is evolving. In today’s era of electrification, digital disruption, and global complexity, Toyota is embracing…

-

Continue reading →: Building a Stronger Improvement Community in New Zealand

One of the challenges for improvement professionals in New Zealand is staying connected — finding peers who “get it,” who understand the daily realities of leading change, and who can share what’s really working in their organisations. That’s why I’m excited about the Enterprise Excellence Group Community, a professional network…

-

Continue reading →: Lean Thinking for a Resilient and Sustainable Community

This week I’ll be attending the NBS Strong Community Symposium in Māpua, where one of the key themes is “Minimising Your Footprint” — building long-term resilience by reducing emissions and adapting to climate change. It’s a vital conversation for our region. Climate events, supply chain disruptions, and resource constraints are…

-

Continue reading →: Aligning Leadership, Strategy and Culture

Turning “words on the wall” into daily action I recently had the pleasure of joining Brad Jeavons on the Enterprise Excellence Podcast to talk about a topic that’s close to my heart — how organisations can truly connect their people, culture, and strategy to achieve sustainable improvement It’s a conversation…

-

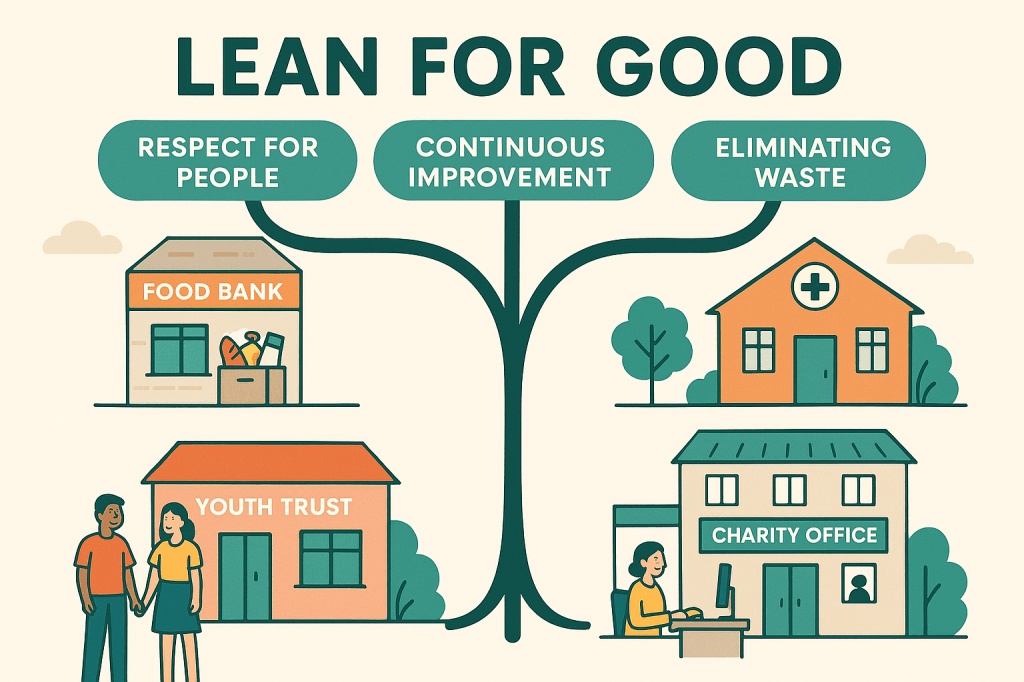

Continue reading →: Lean for Good

Continue reading →: Lean for GoodLean for Good: Bringing Continuous Improvement to Where It Matters Most For most people, Lean thinking is something that happens on factory floors or in corporate boardrooms. But the truth is, the principles that drive operational excellence — respect for people, continuous improvement, and eliminating process waste — have just…

-

Continue reading →: 5S? More like 3S Actually

Continue reading →: 5S? More like 3S ActuallyI recently started working with a Japanese corporate here in NZ, who although expert exponents of continuous improvement in the home country, need a little help and guidance in the land of the long white cloud. I was duly informed that they wanted the original version of 5S, which is…

-

Continue reading →: 5S Find – Unipart Newsletter For Prince Phillip Visit 1995

Continue reading →: 5S Find – Unipart Newsletter For Prince Phillip Visit 1995Having packed up my house in central Auckland about 6 years ago, having had some boxes in storage since, I recently unpacked a couple that I had put under the stairs of my new home. In fairness they had been there for the past 2 years, but with a it…

-

Continue reading →: Eliminating Waste by Seperating Logistics

Continue reading →: Eliminating Waste by Seperating LogisticsOne of my earliest lessons in Lean was to consider the logistical complexities of manufacturing. I have, over the years, laid down a challenge to managers and business owners, to put up a camera with timelapse recording to see how much time people were walking away from their core value…

-

Continue reading →: Shingo Principle: Assure Quality at the Source

Continue reading →: Shingo Principle: Assure Quality at the SourceI have recently been reaquainted with the pursuit of Quality, and enjoying working with the team to solve problems at the root cause. This reminded me of one of my visits on my 2012 Japan tour where we had the pleausure of hearing some of the quality and process improvements…

-

Continue reading →: At Home With Toyota II

Continue reading →: At Home With Toyota IIDuring my Japan Study Tour in 2012 we paid a visit to Toyota Home, the home building division of Toyota automotive. The “Smart Gallery” was essentially a show home which displayed the design and construction of their homes and allowed the visitor to see how Toyota had implemented some of…

-

Continue reading →: Yamaha A Boyhood Dream – Japan 2007

Continue reading →: Yamaha A Boyhood Dream – Japan 2007One my very first trips to Japan our tour included an interesting contrast between a visit to Yamaha musical Instruments and the motorcycle factory and museum. It was a bit of a boyhood dream to visit Yamaha as a teenager I was desperate to own and ride a moped which…

About me

Hi. I’m Richard Steel – an independent Lean and operational excellence consultant.

I was fortunate to complete my initial Lean experiences from 1994 – 1997 with Professor Dan Jones, Toyota, Nissan and Shin-jujitsu consulting.

Over the past 30 years I’ve helped businesses and organisations across industries streamline what they do, cur out waste and build a culture of continuous Improvement.

Let’s connect

Join the conversation!

Stay updated with our latest news and ideas by joining our newsletter.