AI for Toyota?

For decades, Toyota has been the global benchmark for operational excellence through the Toyota Production System (TPS) and its core principle of Kaizen—continuous improvement. But even the gold standard of Lean manufacturing is evolving. In today’s era of electrification, digital disruption, and global complexity, Toyota is embracing artificial intelligence (AI) to amplify productivity and sustain its competitive edge.

Why AI for Toyota?

Despite TPS’s legendary efficiency, certain processes resisted conventional automation. Manual, repetitive tasks consumed thousands of hours annually, and Toyota faced a shortage of AI specialists to scale digital transformation. Rather than centralizing AI in an “ivory tower,” Toyota democratized it—putting AI tools directly into the hands of factory workers.

This approach aligns perfectly with Lean’s respect-for-people philosophy: empower those closest to the work to solve problems.

The Breakthrough: Democratizing AI on the Factory Floor

Toyota built an in-house AI platform using Google Cloud’s infrastructure, enabling frontline employees to create and deploy machine learning models without coding skills. This no-code approach allowed workers to design solutions quickly and independently.

Key enablers:

- Technology Backbone: Google Kubernetes Engine (GKE), Cloud Workstations, and web-based apps for model creation.

- Ease of Use: Drag-and-drop interfaces for building ML models, integrated with existing manufacturing systems.

Impact on Productivity and Kaizen

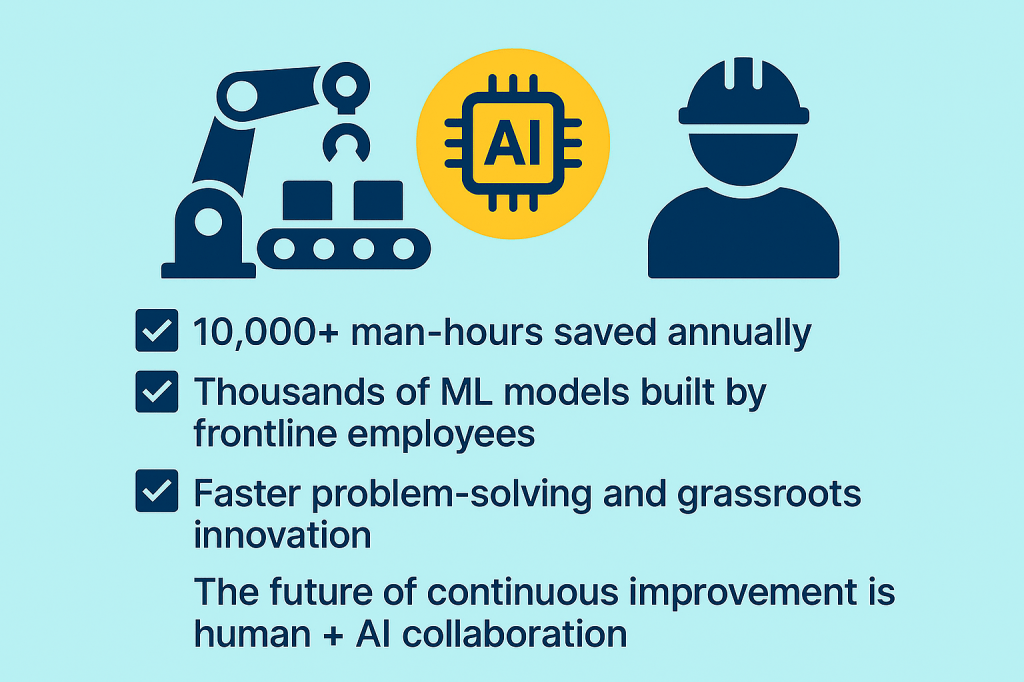

The results have been transformative:

- 10,000+ man-hours saved annually through automation of labor-intensive tasks.

- 20% faster model creation, accelerating problem-solving cycles.

- 10,000+ machine learning models built by workers, not engineers.

- Cultural shift: Empowering 1,200+ factory workers across 10 plants to become AI innovators.

This approach reinforces Kaizen by enabling continuous, grassroots improvements—now powered by AI. Instead of waiting months for IT or data science teams, workers can implement solutions in hours.

Why This Matters for Lean Practitioners

Toyota’s move signals a new era for Lean and Continuous Improvement:

- AI is not replacing Kaizen—it’s amplifying it.

- Respect for people now includes giving workers digital superpowers.

- PDCA cycles remain relevant but are accelerated by AI-driven insights.

For consultants and businesses, the takeaway is clear: AI is becoming a core enabler of Lean, not a competitor. Organizations that integrate AI into their CI frameworks will unlock unprecedented efficiency and agility.

Closing Thought

If Toyota—the pioneer of Lean—embraces AI to sustain Kaizen, what’s stopping your organization? The future of continuous improvement isn’t just human-driven; it’s human-AI collaboration.

Leave a comment